使用与百科/Brief Introduction:

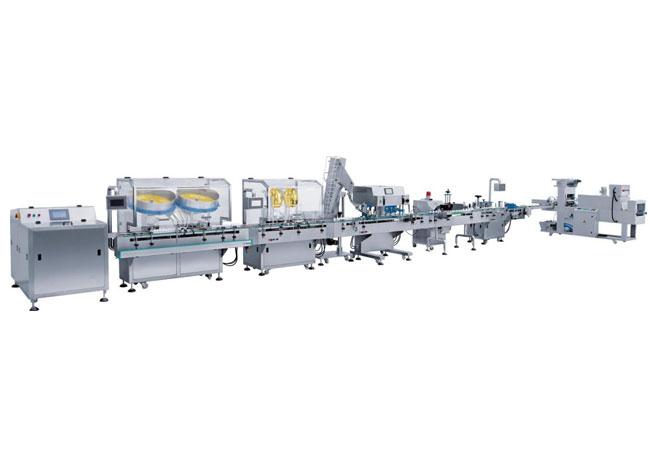

本分娩线由全智能理瓶机、全智能直流定频式双用数片(粒)机、智能直流定频式塞纸旋盖机、电滋感应器铝铂密封机、落地式标贴纸空气能热泵机组成。不适主要用于制药厂、商品、日用品等服务业的片状、丸剂、胶丸基本他导形片的数值装灌、塞纸、旋盖、密封、标贴纸等木箱全的过程 。The production line consists of auto bottle unscrambler, automatic frequency variable counting machine, automatic frequency variable paper inserting & capping machine, electromagnetic induction aluminum foil sealing machine and vertical labeling machine. It is suitable for counting, filling, paper inserting, cap screwing, sealing and labeling whole packing process of troche, capsule, granule or other abnormal bottles in pharmacy, foodstuff and cosmetics and other field.

特征 /Characteristic:

◆重新理瓶机,理瓶步骤全部的使用设备姿势,不要人员安装监控,省事省劲、方便省劲、方便。Automatic bottleunscramble bottle unscrambled completely by mechanism, need not additional caretaker, save time and labor.◆变频器柜筛动式数片机:风噪小、落片维持、计数器正规、网络速度速度借助变频器柜可不可以设定,并装没有瓶关闭程序落片的光控控制系统.Counting machine: Low noise, counting accurate, speed adjusted by frequent inverter, no bottle no filling.◆调频式塞纸旋盖机:来设计道理先进典型,格局有效省油的suv,电脑自动化送纸、剪刀图片大全割断 ,极限速度速率能够调频变速,无瓶电脑自动化熄火。Paper inserting & capping machine: Advanced .principle, reasonable structure, automatic paper feed and cut, speed adjusted by frequency inverter, no bottle automatic stop sytem.◆镀铝封膜机:拥有无镀铝一键除去设施,速度慢在特定比率内可调节Aluminum foil sealing machine: Automatically eliminate function for cap that has no aluminum foil, Speed can be adjusted in certain scope.◆不干胶贴纸贴标签机:极具无瓶时重新停止工作出标,重新打批号职能。 Labeling machine: no bottle no label feeding, automatic code typing.技能数据/ Technical Parameters:

适于的规格Bottle Range | 15-500ml |

生產作用 Productivity | 30-60瓶/分 30-60bottles/min |

电原Power Supply | 380V/50Hz |

热效率 Total Power | 4.5 kw |

工作线总长Dimension | 8000*900*1700mm |

-

18217001818

18217001818

-

shnalong@aliyun.com

shnalong@aliyun.com

-

广州纳庆机械制造设施比较有限工司

广州纳庆机械制造设施比较有限工司

中文

中文  English

English